Most domestic beers (and most imports) are designed by the brewery to be served with just a

small bit of carbonation. We can maintain this balance of carbonation with our pressure gauge

set to 12 PSI. But if your secondary (step-down) regulator is set a bit higher, maybe 15 PSI or

more of straight CO2, then you are slowly over-carbonating your keg. This is not usually an

issue if the keg is used within a few days. But for kegs that sit tapped for weeks at a time or

longer this can become a concern.

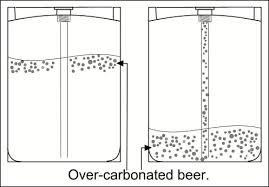

You can see above that you draw your beer

from

the bottom of the keg, so you don't begin to get the lighter,

foamier

over-carbonated beer until you reach the last of the keg.

Ideally, we keep it from getting

over-carbonated in the first

place. But if it does happen, there are a couple of tricks

you

can use.

Here's what you can do:

1. Keep the beer cold. The colder

the better.

34 degrees is better than 38 for reducing foam

in

slightly

overcarbonated beer

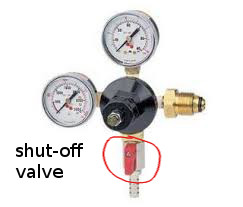

2. Make sure the regulator that

controls the pressure to the keg

is set no higher than 12 PSI.

3 . De-gas the keg.

-

Shut the gas off to the keg at the regulator

(hopefully there is a shut-off valve)

-

Open the safety release valve on the keg to release the gas

The safety release is circled in red, pull the ring out to release

the head pressure on the keg. -

Shake the keg for 15 seconds

-

Wait 3 minutes, then open the safety release valve again to vent

the carbonation you just stirred up. -

Turn the gas back on to the keg at the regulator.

Do not make the mistake of trying to adjust the pressure of the

regulator down, because the reduced

pressure will allow the

Carbonation in the slightly over-carbonated beer to "Break out"

of

the

beer and foam in the line, just behind any connections or the

shank of

the faucet.

This will make the problem worse, not better.

To make sure your regulator is set to

maintain the perfect, ideal conditions for your beer,

call one of our

Draught Beer specialists to come give you a free estimate for

the

repair

or installtion of a Beer Dispensing System. Intalls

Repairs

The

best

way to fight this is to make sure all conditions are as close to

ideal as we can realistically make them. The lines are

straight

or smoothly curved (no "elbow" joints), the pressure is just

high

enough to dispense smoothly, not too much. The lines are

clean,

the beer is cold, and the lines are being cooled, chilled, or at

least

insulated all the way to the dispenser. Remember, if

the

beer warms it will release the co2 gas.. so if it gets warm in

the

tubing on the way from the back room or beer cooler out to the

bar,

then it will foam IN THE LINE, and this will cause your beer at

the

dispenser to come out alternately clear and foamy, depending on

how

many "hot spots" you have along the line.

Call 713-944-7900 to schedule a Service Call.